Update to the 5 gallon dust separator

I made a screen for the bucket separator, which in theory should force the dust to go down into the bucket better and keep the turbulent flow up above. Using the CNC machine I cut a piece of scrap wood to fit into the bucket with a gap around most of it to allow the material to fall into the bucket. I think the support posts create too much turbulence within the bucket itself and this causes more of the fine dust to get into the vacuum. Perhaps I need to just have a small screen not much larger than the central portion of the bucket to allow for less turbulence and faster fallout of the larger particles.

This system relies on centripetal acceleration to push the particles to the outside wall of the bucket, as gravity causes them to settle out of the airflow they fall below the screen where the air is much more calm and there they fall out completely. What I found is that the bottom of the screen was coated with the smaller particles, while the smallest particles made it back into the vacuum, clogging up the filter. The large particles were intercepted into the bucket. The whole point of this is to reduce the amount of buildup on the filter. I will try with a smaller screen. At this point I think it worked better with no screen at all, however the true test will be this weekend when I put it into actual service, instead of merely testing with a pile of sawdust dumped onto the floor.

Some images of the bucket lid and screen. I must say I am very pleased with the CNC machine, and would not be able to manufacture my own tools to the tolerances I expect without it. Perhaps I will have to use it to manufacture a larger CNC machine, something with a bed size of 36″ square or 36×48. That will be a major project. Until then I’ll just use it to make other tools and jigs.

CNC Coupling Nut

During cutting of the handles for the bee boxes I had the issue of the z-axis coupling nut slipping. This destroyed one of the sides, as the CNC stopped raising the tool, it ended up cutting all the way through the box. In order to fix this I made my own coupling nut by tapping a 1″ nylon bushing for the threaded rod, and pushing it onto the stepper motor. I have had no issues since I did this. I will try replacing the other two as well. Perhaps I can increase the speed of the movements. This would greatly reduce the necessary cutting time.

Cake pop stand

Christmas is when I get to work making presents. This year I had a request. A cake pop stand. Here is the finished product.

Its made entirely out of melamine mdf. Easy to clean and no finishing required! Just don’t look too closely at the edges.

Hope she likes it, she needs it for a party tonight and its been done for about 10 minutes.

Christmas

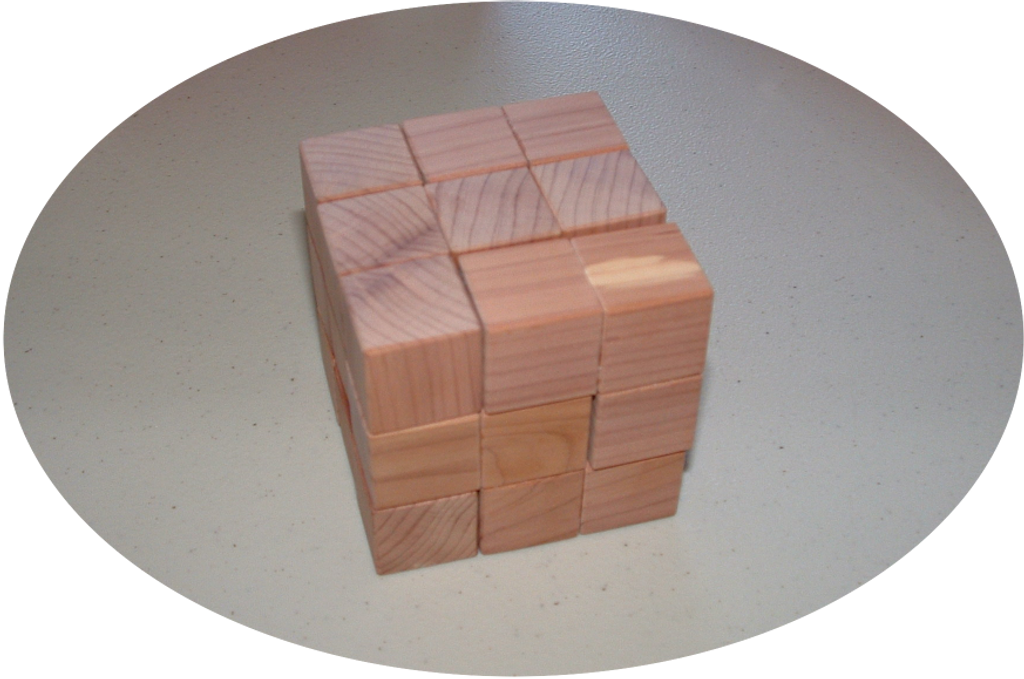

Besides the AWESOME gifts I got this year, I had a great time making a few gifts. Two of them were wooden logic puzzles. The first one, a ‘Soma Cube’, was discovered by Piet Hein in the mid 1930’s. There are exactly 240 unique arrangements of the seven pieces to form a cube. I made this puzzle out of aromatic cedar.

The second puzzle is the ‘Half-hour Puzzle’, created by puzzle-master Stewart Coffin. This puzzle is slightly harder than the Soma Cube with only 1 solution for the 6 pieces. I made this puzzle out of cocobolo.

I got the plans and instructions on how to make these from this book that Laurie gave me a few years ago for Christmas.

These turned out well, and I learned a few tricks to speed up the process. The best part is that the recipient of the first puzzle wasn’t able to put it down all day.